Vittoria has been in the cyclocross tire market for decades, and the company recently released the Terreno line that reflects the newest in the company’s material and design technology.

Vittoria teamed up with Cyclocross Magazine to sponsor a series of three posts to tell the story of the design of the new Terreno cyclocross tires. Cyclocross Magazine spoke with Ken Avery, Vittoria’s Vice President of Marketing and Product, to take a deep dive into the design of the new Terreno line.

Today’s Mechanical Monday p/b Vittoria looks at the Terreno Wet cyclocross mud tire.

In the final Mechanical Monday p/b Vittoria post, we will be looking at the new Vittoria Terreno Wet cyclocross tire. We will also look at some of the technologies Vittoria brings to their cyclocross tires to help enhance their performance.

Our first Mechanical Monday p/b Vittoria looked at the design of the Terreno Dry and last week’s covered the Terreno Mix.

Cyclocross Magazine has previously looked at the Terreno line that comes in 31 and 33mm tubular and 31, 33 and 40mm tubeless versions. The new tires are built with Vittoria’s 3C layering process that uses three different compounds within the tire and the G+Isotech Graphene compound.

Cyclocross Magazine’s Zachary Schuster spoke with Ken Avery of Vittoria, who has nearly 20 years experience in the industry, about the details of the design of the Terreno Wet. Ken is a self-professed tire geek who brings both a micro and macro-scale perspective to tire design and the features that are packed into a 31, 33 or 40mm tire.

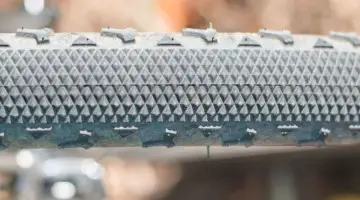

Vittoria’s new 40c Wet tread has been a good all-conditions tubular tire in our tests, and the 40c version should be a good option for soft and wet conditions. The siping on the knobs increases suppleness, while the tread is designed to clean mud and debris as the tire rolls forward. 2017 Sea Otter Classic. © Cyclocross Magazine

Interview with Vittoria’s Ken Avery about the Terreno Wet

CXM: Before we get to the Terreno Wet, I wanted to touch on something that has played an important role in our discussion. Your website says the 3C compound is “where you need it the most.” Where are those locations?

Ken Avery: Our mountain bike tires use 4C technology, and for our Terreno cyclocross tires, we opted to use 3C based on their intended use. The layered compound gave us the ability to build a more versatile profile into the tread.

First, it gives you a stable base compound. The base of your tread is going to stay where it was designed to be and not just flop over. It then gives you a softer performance-based compound where the tread is actually hitting the ground.

For the compound layups themselves, the center tread is going to be more biased toward faster rolling and the side treads are going to be biased toward more cornering grip.

That mixture allows for a product that, in an overall sense, works the way you want it to work. You won’t necessarily be thinking about why that is, but our factory has special tooling that can put these compounds exactly where we want them to be on the tire.

The coolest thing about Vittoria is that you have the high-TPI, handmade, hand-sewn cotton casing combined with our high-tech compounds and tread designs nobody else has. That’s something that really sets us apart.

CXM: Today we are going to talk about the Terreno Wet. How did you come up with the tread design and how does it work?

KA: Mud tires are certainly something everybody’s got an opinion on, and I really think we made a tire that applies our no-compromise approach. What’s the first thing people say if you ask them, “How does a wet or mud-specific tire roll?”

CXM: Poorly?

KA: Rolls slowly, right? We wanted to make the fastest-rolling, most capable mud tire ever made. That’s a big, big challenge, but go big or go home. I really feel we made something special with the Terreno Wet.

Why do wet mud tires roll slowly? Wet or mud tires have a really capable tread that digs down to paddle the mud and move the rider forward, but at the same time, you need a good amount of spacing so the tread doesn’t pack up and can clear itself as it rolls. It’s hard to do, and we’ve kind of pulled out a couple tricks with this one.

The first is the tread has what’s called an alternating center ridge. When you look at a lot of tires, there will be a line of symmetry down the center. The left and the right are mirror images of each other. On the Terreno Wet, the left and the right side treads are identical but they’re staggered by essentially half a period of the tread.

They also kind of interlock. If you look at this tire, it looks very aggressive, but if you roll it in the work stand, you’ll actually see something that looks like a center ridge.

Robert Marion, aside from being a top pro racer, owns a bike shop. He was so moved by this tread that he even said, “I would almost sell this as the one tire you need because it’s capable in the mud but then it still rolls fast everywhere else.” I was shocked that he had that kind of an input on it.

Michael van den Ham looked at it at first and he asked, “Is this aggressive enough?” He took the prototypes to Belgium last year and he raced them in the famous peanut butter mud everybody likes to romanticize about, and he came back and he said, “Nope. It’s perfect.”

He said, “I would not change a thing about it. I take back any concern I had about it not being aggressive enough. It is fully capable and it rolls faster than anything else.” That’s all I could ever hope for from getting these types of emails from our athletes.

With this tire, if we just had a row of paddles, it would scoop you out of a mud hole, but then it’s going to roll slowly everywhere else. The alternating center ridge tread pattern provides aggressive paddles in the center and mid tread, and then there are also cleat knobs on the side. The tread digs into the mud and throws it off but at the same time, as the tire rolls forward, you minimize rolling resistance.

Jennifer Malik of the American Classic team ran the Terreno Wet at the 2017 Pan-Am Championships in Louisville. © Z. Schuster / Cyclocross Magazine

CXM: It seems like there is a decent amount of open space on the Wet to clear mud. How did you balance leaving it open with having tread on the tire?

KA: Yeah, that was definitely a challenge, but I think the negative space between the treads is another cool feature of the Wet. Imagine you’re riding a bike and looking down at the front tire; you can see that V pattern that points forward on the top of the tire.

When you look at the negative space on the Terreno wet, you can imagine a V that points toward the back of the bike. Those spaces are actually the evacuation channels.

The coolest thing about the Terreno Wet is while you corner, it’s cleaning itself. As you’re putting a force on it, it’s going to dig down further into the corner and actually clean itself out, which is pretty crazy if you think about it. That feature was designed into the tread so you don’t have something that just packs up as you push harder.

The cleat and outer knobs are designed to puncture the terrain and dig down into off-cambers and other tough features. This is a tire you can use to go really hard into an off-camber knowing it’s going to give you mountain bike grip but with a rolling resistance similar to a Vittoria road tire.

CXM: Looking at this design, it looks like siping plays an important role on the Terreno Wet, right?

KA: On even the muddiest cyclocross course, you’re going to go from a grassy, muddy, gross part to either some gravel or pavement when you go through the start/finish area. That transition is usually unavoidable.

If you have a slow-rolling tire, you’re going to lose speed on the hardpack sections, but at the same time, if you have a more traditional mud tire with solid knobs, it may also make that transition difficult.

By adding siping on the Terreno Wet, we were able to increase the flex in a given direction. It’s engineered into the Terreno Wet tread so when it hits the hard pack terrain or pavement, it’s going to give you a tremendous amount of grip even though you’re just basically standing on top of an aggressive mud tire.

CXM: So does that provide some of that flexibility and some of that grip on those off-cambers, is that kind of the idea behind that?

KA: It does. If you think about it this way, forward grip on those knobs is not going to be the challenge. What’s going to tough is maintaining alignment on an off-camber. You don’t want to have the tire slide sideways.

By putting the sipe from front to back, you allow the flex in a sideways direction. That makes it nice and gummy in the direction you’re using to oppose that sliding. However, it doesn’t give you any sort of a negative effect when you’re rolling forward. The direction of the siping plays a huge role in how this tire works.

The siping is easy to see on the Terreno Wet. © Z. Schuster / Cyclocross Magazine

CXM: You wouldn’t want that on the backside because if you’re braking, then it would just get all shredded up, you want that solid more square design that also looks like it’s designed to shed off the mud, right?

KA: Yeah, exactly. If you go one knob in from the side to the mid tread area, you have a really nice square edge for braking, and if you sink down into the terrain, those also give you a nice little miniature paddle cleat that will throw you forward.

But let’s say you hit your brakes on wet pavement. The siping on those will give you a nice surface tackiness that will still hook up on the wet pavement and give you a really consistent feel.

CXM: It seems like you are asking a lot of these tires. Did the 3C compound play a role in how these were designed?

KA: The answer is without our compounds, we absolutely could not have done this. If we used the basic single compound a lot of cyclocross tires have, they’re not going to flex as needed to take advantage of these tread design features, or if they do flex, they’re not going to be supported by the base compound the 3C offers.

The Terreno Wet has one compound at the base of the knob and then another further up toward the surface of the knob. When you flex one of these tires, the base of the knob stays very stable and firm but the top of the knob that engages with the terrain is nice and compliant.

The 3C and Graphene compounds we use also allow the Terrenos to maintain their performance in cold weather, which becomes more important as we move toward winter. We did temperature-based durometer testing on our tires and a lot of our competitors. The durometer is a measure of rubber hardness.

We found a lot of our competitors’ tires feel good at room temperature, but when you put them in sub-freezing temperatures, they become rock hard. Their performance drops off sharply. We were able to use compounds that are temperature-stable, so the Terrenos don’t have that type of performance drop off in cold conditions.

You mix our 3C technology with Graphene with the temperature-stable compounds with all the tread design tech and that’s the reason that we’re sitting here today talking about the Terrenos.

The Vittoria Terreno Wet features an offset center tread and a healthy amount of space for clearing mud.

CXM: Everything you have described with the Terreno Wet sounds very ambitious. You don’t have to give away any secrets, but how do you hammer in on, “Here’s what we want to do, here’s how we can do it,” with the design.

KA: I have a process I go through when I start sketching designs and developing ideas, but at the end of the day, I kept thinking back to what all the athletes were telling me they wanted. They provided great input and we certainly had lofty goals to give them something they would be happy with.

Our athletes are an interesting group. Some are more vocal than others, but they all have opinions about what they want to see. I’m Adam Myerson’s biggest fan, but at the same time, you get him in a conversation where you have some different opinions and it can turn pretty funny really fast.

Then you look at someone like Justin Lindine and he basically said, “I don’t even care. I just want the thing to hook up.” He has a diesel motor and he rides differently than a lot of other riders. Then you’ve got Van den Ham and Marion, who I would say are a bit more varied in how they ride and what they want.

From a tread and product design perspective, the tread on the Terreno Wet just seemed to make sense. We needed to have enough room to allow it to clean itself out. The tread needed to be deep enough but not too deep. The siping had to be going in the correct directions based on what you’re trying to achieve on each part of the tread.

Things that have been done before were certainly considered but at the same time, what we didn’t want to do is make something that looked like what had been done before just to be consistent with other things in the market. At the end of the day, the things in the market weren’t working the way we wanted them to do.

We felt like we had to do something different. Vittoria is a leading manufacturer of mountain bike tires, so we took a lot of knowledge from our experience there. We have the number one UCI trade team on our product, and I test with them every single race. The Graphene and 4C compounds and the technical tread designs have been the foundation of our mountain bike program.

With the Terreno line, we took all these great things and evolved what we’ve previously done by putting it on our cotton-based casing. We added the athlete feedback and put it together in one package. It’s not surprising it is something different.

CXM: I have one last question. We’ve talked about three different tire treads in the Terreno line. What are your thoughts about mixing and matching them?

KA: Sometimes riders will prefer to have something a bit more aggressive in front if the course gets a little slick. The theory is they might be running the ups anyway in those conditions, so they’re really just trying to survive in the twisties. Some people will run a Mix in front and a Dry in back or even a Wet in front and a Mix in back. I’ve seen that done.

For the most part, riders run a matched set with the Terrenos. The reason I say that is the tread designs are so capable in a range of conditions that you don’t need to pigeonhole each as much as you would with a lot of other tires.

When we talked about the Dry, I said so often people will run a file tread in only the perfect scenario and that’s it. Now we’re seeing people run our Dry all the way through the midseason. Previously, you wouldn’t have been able to do that.

If our tires had the limitations of a lot of other tires, I would say yeah, you might have to mix and match if you have in-between conditions, but with the Terrenos, that’s not as much of an issue.

CXM: Thank you. This has been incredibly interesting for me, and I imagine our readers will feel the same.

KA: You’re welcome, it’s been fun.

More info about the Terreno Wet: vittoria.com