Vittoria has been in the cyclocross tire market for decades, and the company recently released the Terreno line that reflects the newest in the company’s material and design technology.

Vittoria teamed up with Cyclocross Magazine to sponsor a series of three posts to tell the story of the design of the new Terreno cyclocross tires. Cyclocross Magazine spoke with Ken Avery, Vittoria’s Vice President of Marketing and Product, to take a deep dive into the design of the new Terreno line.

Today’s Mechanical Monday p/b Vittoria looks at the Terreno Mix all-around cyclocross tire.

In this second of three Mechanical Monday p/b Vittoria posts, we will be looking at the new Vittoria Terreno Mix cyclocross tire. We will also look at some of the technologies Vittoria brings to their cyclocross tires to help enhance their performance.

Our first Mechanical Monday p/b Vittoria looked at the design of the Terreno Dry.

Cyclocross Magazine has previously looked at the Terreno line that comes in 31 and 33mm tubular and 31, 33 and 40mm tubeless versions. The new tires are built with Vittoria’s 3C layering process that uses three different compounds within the tire and the G+Isotech Graphene compound.

Cyclocross Magazine’s Zachary Schuster spoke with Ken Avery of Vittoria, who has nearly 20 years experience in the industry, about the details of the design of the Terreno Mix. Ken is a self-professed tire geek who brings both a micro and macro-scale perspective to tire design and the features that are packed into a 31, 33 or 40mm tire.

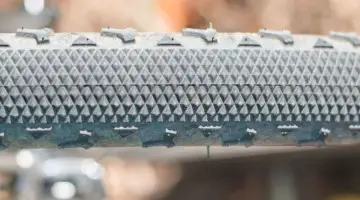

Vittoria’s new Terreno Mix features a more traditional design that balances speed with mud clearance and traction. 2017 Sea Otter Classic. © Cyclocross Magazine

Interview with Ken Avery of Vittoria about the Terreno Mix

CXM: Today we wanted to talk about the Terreno Mix. With this tire, what were you trying to accomplish?

Ken Avery: The mixed tire is something that if you’re going to have a set of tires, you’re going to want it to be able to perform in the broadest range of conditions possible, right? Not everybody can have three sets of tires. If you’re a guy or girl who just wants to go and race a couple cyclocross races a year but then be able to do some adventure or gravel rides, you might not want to get as specific as having something that’s just designed for one use.

With the Mix, we wanted to design a tire that works in a mix of conditions, not surprisingly. That goal was incorporated into the tread profile

When you have mixed terrain, you’re going to have some hard pack and some surfaces where the tread sinks it. You’re going to have a little bit of both. Because of that, the Mix uses a pretty pronounced center ridge that rolls very fast. It’s something that is going to keep you on hard surfaces where the tread doesn’t dig in and it’s going to give you very low rolling resistance.

When the tread does sink in, then the arrow pattern in the center tread will allow for two things to happen. The first thing is, if you get into soft terrain, it will kind of tractor paddle forward to provide forward traction. The cool thing is because it’s sort of an arrow that keeps the V formation we spoke about earlier, it’s also going to give you sort of like an automatic cleaning benefit.

Let’s say you’re trying to climb up a grassy hill. The Mix will dig down to harder terrain to create that traction for you. At the same time, it purges everything else out the side of the tread to make sure that that center tread stays clean. That’s kind of a cool design feature within the tread.

The backside of that arrow also gives you a nice, broad braking paddle. If you’re coming down a similar feature, it’s going to give you a tremendous amount of braking traction.

The cool thing with the center tread is when you’re on hardpack it’s going to give you very low rolling resistance, but if you get into a mixed condition or soft terrain, it’s going to give you all that evacuation, cleaning, cornering and braking. We wanted to be able to achieve both with the center tread.

“I finally got to ride the Mix and also love it! The side knobs are tall for a mix and actually bite. They really fix what I’ve disliked about other chevron-style treads.” – Erin Faccone

For the side tread, we wanted to make sure there was enough room for the effective edge to work. Often with mixed-terrain treads, you will see tightly-spaced side knobs and what can happen is the tread will pack up and once there is enough dirt in it, the effective edge can’t work. It almost becomes like a dirt slick.

With the Mix, we wanted to make sure there was enough room between the center and the side knobs so the side tread has enough room to work on the inside effective edge when you lean on the tire.

Then lastly, you’ll see what one of the riders who I can’t name called “the snake tongue,” which you’ll see repeated in the center as well as the side. There is a block that has sort of like a split tail. It’s like a swallowtail surfboard.

The side tread on the Terreno features a block with a split tail that serves multiple functions. 2017 Sea Otter Classic. © Cyclocross Magazine

The block is very rigid, but the tail of it is nice and soft. If you were to look at that V formation on the tire, you can kind of connect the dots between the ones that have that swallowtail on them. That gives you a nice firm block that stays in place as you want it to, but at the same time, that edge is nice and compliant and kind of squishy. It works sort of like a sipe, but it’s just a different way to accomplish that.

Then that little round cleat between those offers a bit of evacuation. That round cleat will definitely dig in but at the same time, if dirt needs to come out and squeeze around that to clean out of the tread, it’s like an evacuation path.

CXM: Looking at the tire, there also looks like there are some small raised features on the outside of the tire as well. Is that part of the design or is it more of an aesthetic thing?

Ken Avery: That was definitely part of the design. We went in circles on this with a couple people, and you know, there are a couple brands that use something similar and we’ve called it ribboning. We’ve actually called it all sorts of different things internally.

There are a couple key things with that. First of all, we wanted to make sure that the side tread was far enough up the casing that it would engage sooner when you lean on it. What I mean by that is so often you’ll see a tread profile that’s really round in profile. If you think about how far you’ve got to lean over for those side knobs to engage, you’d be nearly dragging your bar on the ground. And even if you were to get over that far, there’s going to be so much force, you’re just going to overrun the tread and the tire is going to slide anyway.

With this particular model, we wanted to have the shoulder knobs kind of come up the casing a little bit more to engage a little sooner since it’s a mixed terrain tread and you are likely to want to do more things with it.

That riveting on the side does a couple things. It offers a bit of tread rigidity for the actual tread band on the tire itself. It also adds a bit of protection there as well in case of either pinching or abrasion. It does add aesthetic value as well. It has that old-world European kind of look to it in a way, but there was an actual reason for it being there as well.

CXM: I have run other tires and have had issues with mud packing up because of tight spacing on the tread. How did you decide how much spacing to put on the mid-tread area?

Ken Avery: The Mix has a very tight center tread, but it’s a very open mid-tread. With some tires, it’s like you have tight spacing everywhere or open spacing everywhere. This tire has a tight center tread, which will roll very fast on hard pack, but then an open mid-tread that engages when the tire sinks in.

By doing it this way, you kind of have the best of both worlds in that you have an open tread that will clean and the side tread has a nice, open space for dirt to pack against the inside edge of the knob that is cornering, but at the same time, you don’t sacrifice rolling resistance. It’s definitely a delicate balance but the key differentiator with this particular tire is the center is tight but then the mid-tread is very open.

You know what’s funny, we did a contest on social media where we said, “Pick your favorite Terreno,” and the Mix actually won. I was actually surprised because we’ve gotten so much feedback on the dry from all the gravel guys and how it’s kind of a revolutionary tread compared to a lot of other file treads, but each one of these treads is quite special.

I think a lot of people really look at that mixed tread and they say, “Wow, I really could do pretty much almost everything with this thing.” That’s been something that’s been really encouraging.

Adam Myerson ran Terreno Mixes for part of his National Championship ride in Hartford. 2017 Cyclocross National Championships, Masters Men 45-49. © A. Yee / Cyclocross Magazine

CXM: The Mix has more of a traditional design with the chevron shape. Was there a reason besides why you decided to kind of go with that more traditional approach to this design?

Ken Avery: There are a couple of reasons. First, cyclocross is just so silly sometimes.

CXM: No way.

Ken Avery: There’s such a strong cultural component to cyclocross. There’s so much romance with the old-world cyclocross culture and a lot of people talk about Europe and how the dirt tastes and all sorts of different things.

We wanted to make sure that we had something that fit the style. That is another challenge with any kind of product design. You’re already up against the crazy wall of challenges with trying to just get all of the performance in different terrain types and everything else, and then it also has to look cool.

It’s an amazing challenge, but admittedly the Mix looks a bit more traditional than the other two. We definitely still designed something that I feel is ground-breaking and different, but it’s a different take on a traditional profile. A lot of those traditional profiles are going to have an even spacing of one form or another, whereas this has just such a variance.

You have that traditional aesthetic but you have so much new world technology that just really sets it apart.

Vittoria’s Mix uses a more traditional design than the Dry or Wet models. 2017 Sea Otter Classic. © Cyclocross Magazine

CXM: We had a question about tire casing. You go with cotton for your tubulars. Why did you pick cotton? What kind of blend is it?

Ken Avery: Cotton is something Vittoria has been using for decades. The company is almost 70 years old now. We’ve won every Grand Tour. We’ve won Olympic medals in different disciplines.

We’ve learned a lot throughout the years with track and road. We’ve been using a cotton-based casing on our cyclocross tubulars for many years. With the Terreno line, we’re able to evolve it into something that is kind of a step beyond what we previously had.

The request we’d been getting from riders was to make something that was as ultra supple as we can make it. Many of them also had ideas of how to make it even more supple. The idea behind that is not just about feel. It’s definitely about feel, but it’s also about rolling resistance and how it hits a bump and things like that. The purpose of a high TPI supple casing is to reduce deflection.

If you were to hit a root say or something that’s in the ground, let’s say a small but square-edged and pronounced bump. If your tire bounces off it, it’s going to produce more rolling resistance than it would if your tire can absorb the impact and morph around it.

We wanted to make sure we used something that we had a lot of background knowledge in and tooling for as well something that’s accepted in the market like cotton. But we also wanted to put a spin on it and make an improved version.

There are a few things you get with our cotton casing. Many times the downside of a cotton casing is it can be fragile if it’s not made correctly. Somebody spends the trouble of getting these expensive tubulars from another company and they glue them up and then they cut the side wall. That’s just a bummer.

Our tubulars have a blend called Corespun K, which is something that we also use on our Corsa, which is an array of reinforced blends of cotton, so they’re much more impact resistant and much more cut resistant. That’s number one.

For number two, so often times you’ll see people talk to their friends or in forums and say, “Oh yeah I need this supple casing. I need this. I need that.” And then they put four pounds of aqua seal on the side of their tires. It cracks me up. I’m like, “Dude did you not understand that you’re destroying everything that you are hoping to gain from this cotton casing?”

The cool thing about the Vittoria cotton casing is that it comes pre-sealed from the factory. The tires are coated in a very thin coat of latex. You don’t have to worry about sealing your tubulars. That’s something that everybody from Michael van den Ham to Adam Myerson and others said they did not have to worry about anymore. It was kind of a relief even for them.

We’ve gotten to the point where I would put our casing right up against anybody else’s casing. It’s to the point where some of our riders were saying that they are actually running a PSI or two higher in our tire because it is so supple that they were able to run a little bit more pressure if they wanted, giving them a little bit better rolling while still being able to hook up in the corners. That was kind of a cool side benefit that came out of the testing.

Adam Myerson’s Vittoria Mix tubulars and their cotton casing stood up to the elements at Hartford Nationals. 2017 Cyclocross National Championships, Masters Men 45-49. © A. Yee / Cyclocross Magazine

CXM: Along those lines, can you explain the TNT tubeless technology and what it offers for tubeless setups in cyclocross?

Ken Avery: It’s a tubeless-ready bead, which has a different shape than a traditional bead. The idea is that it locks into the hook on your rim in a different way than a regular tear-drop shaped bead would. That helps eliminate burping and things like that.

Aside from that though, the chafer, which is just above the bead, the black strip that encompasses the bead, has been beefed up a little bit so it’s much more robust on the TNT tires. It also helps lock that bead in.

When you mount a TNT tire, often times you can do so in the parking lot with a floor pump or a hand pump, which is something that blows people away. It used to be like, “Make sure you have your compressor,” but with these, you really can pump them up on-site if needed.

That was our goal, and for 95% of the wheels out there, it’s not an issue. Sometimes you’ll get a weird, older-style wheel that is “tubeless ready” but was maybe from the first wave of tubeless technology that is difficult to mount the tire on, but more often than not, it’s a seamless process.

Thom Parsons has a series of videos on dirtwire.tv where he will be working on wheels very casually, maybe while he’s making coffee, and it’s always entertaining to watch him pump them right up. The TNT tires offer a very pronounced snap when they pop in the bead. That’s the bead technology.

The sidewall is a 120 TPI casing. The TNT with the gray sidewall has a bit of a sidewall reinforcement, which also helps when running low air pressures and it helps avoid burping and increases durability and longevity without sacrificing performance.

These changes have been something that’s been different than just saying, “Hey, we changed our bead,” and that’s it. It’s a whole family of changes and features that go into the TNT technology.

Stay tuned for the third Mechanical Monday p/b Vittoria next week.