This article originally appeared in Issue 24 of Cyclocross Magazine. First-time contributor and photographer Dan Cavallari was a pro wrench for 14 years, and we loved his story, which is why we decided to share it on here as well as in print. Cyclocross Magazine values community-contributed content such as Cavallari’s awesome photo essay and journal from Nationals, and we’d also welcome any contribution from any mechanic who want to document any activity, including eschewing any alcohol. And it goes without saying, any contribution does not represent the opinions, thoughts, or drinking habits of Cyclocross Magazine.

We decided to run the article in its entirety online after seeing complaints from a few mechanics about the line referring to mechanics drinking beer while working at Nationals in Boulder. Unfortunately for the mechanics seeing this single line without seeing the full photo essay, they didn’t get to appreciate that the article actually celebrates the great job that these professionals do behind the scenes for pro racers, and gives an honest look at what goes on in the team tents at the races.

Water poured into the street, and the pressure washer produced rainbows through the spray on the cold, sunny Colorado day in January, just days before Nationals would commence. Complaints from the town—water in the street is bad for business—meant a last minute shift in the bike wash set-up, which threw workers into a frenzy in a chaotic bid to be ready when the big showdowns started.

Perhaps the most commonly used tool among pro wrenches on the first day of Nationals in Boulder, Colorado, was a hose. An all-day thaw after January snow made muck out of the course, and riders couldn’t have been happier. Anyone holding an Allen key or bottom bracket tool, on the other hand, was perhaps too caked with mud to notice the merry mood. In those moments, mechanics took every opportunity to clean, lube, and adjust so their racers could shift cleanly out on the

demanding course that featured a tough climb, not to mention slippery, off-camber descents.

As the week progressed, high winds dried out the course and the burden shifted for mechanics throughout Valmont Bike Park. No longer was the hose the focus of the pit areas; instead, wrenches found themselves changing tires and brake pads to accommodate the drier conditions. At the WD40 tent, a steady line of racers fresh off the line from the power washers waited patiently for tuneups. Graham Milner of WD40 said, “It’s mostly clean, lube, and protect. That’s it. The bikes coming through are really, really dirty, but it’s good Boulder dirt, and it’s not messing up the componentry.”

The life of a wrench is one of adaptation, modification, and hydration. Get ready for the conditions to change, get ready to swap parts, and keep your stress level low with a beer or Red Bull, or both. During Nationals week, toolboxes in just about all pit areas had a beer or two at the ready, just in case some emergency de-stressing became necessary.

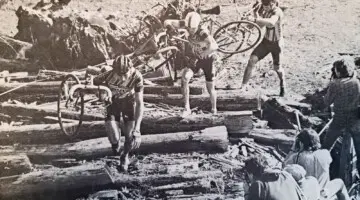

But before and during the races, it was all business. The pit areas stayed clogged with spare wheels and spare bikes. Quick fixes were often all mechanics could get to in the precious pit moments during a race, so the most efficient use of time was often simply a bike swap, sending riders on their way in seconds. Luckily, most of the top contenders were prepared.

Cameron Jacques from Pro Bike Express was anxious for the flurry of activity all mechanics come to know and embrace during races like Nationals. “The hurry up and wait was killing me [early in the week]. I couldn’t stand it.”

Indeed, after those early hours on day one, visiting pit areas was like stepping into a lottery ball machine: movement everywhere in every direction, mechanics bouncing from bike to bike. Keaton Ward, one of SRAM’s many mechanics on hand, was busy swapping out hydraulic disc brakes in favor of mechanical BB7 brakes while SRAM sorted out the road hydraulic disc brake recall. Ward and the other SRAM mechanics had the swap down to a science, with each bike in and out of the stand within minutes. Not a single face looked worn or tired, only focused on the task at hand, while the occasional heckle kept the mood light—this is ’cross, after all.

As conditions dried out over the course of the week, mechanics shifted their attention to tire pressure, torque specs, and drivetrain maintenance. Over at the Shimano tent in the pit area, TJ Grove shed light on maintenance goals: “We’re seeing a lot of bent derailleur hangers and brake activity because racers are using them to steer out on the course.” Grove offered some suggestions for keeping bikes in top shape while on the road. “Do bolt checks on bikes that were packed on the airplane. We all carry torque wrenches because the amount of pressure you put on these nuts and bolts is very important. I think at home everyone should have a torque wrench.”

The best pro wrenches always have the right tool for every job. Sometimes though, a bit of innovation does the job quicker. Over at the Raleigh pit area, James Sullivan, head mechanic for the Raleigh team, showed off a custom-made derailleur hanger alignment gauge. “My buddy made it. It’s half the size and a third the weight of any other derailleur hanger tool and it fits better in my tool roll.”

The trick to making repairs during and between races? “Multiple bikes,” Sullivan said.

Not everyone with a wrench in their hands was a mechanic. Elite racer Rebecca Blatt (Van Dessel) was in the parking lot gearing up for a practice lap, and her car’s trunk was filled with spare wheels and a Home Depot bucket full of tools. “Riding ’cross, you always have to be ready to take care of yourself. You have to know how to fix everything every day.” When asked what was most important about being ready for mechanicals, she said dryly, “Not having any.”

Other riders without official race support echoed the sentiments of the pros. South Africa native Timothy Jenkinson was out racing for Mars Hill University. “I’m expecting a lot of cable changes and a lot of chain wear,” he said as he worked on his own bike in the Industry Nine pit area. His plan was to monitor tire pressure and make sure everything on his bike was torqued, tight, and ready to race. “In these conditions, tire pressure is important. Allen keys are the most important bike tool to have. You can’t do much on a bicycle without Allen keys.”

So true, yet anyone who’s ever raced an Elite race like this one might argue: You can’t do much on a bicycle without a reliable mechanic. Perhaps that’s why the races at Valmont Bike Park were so ferocious, so fast, and so fun: There were plenty of mechanics on hand to make sure that the best of the best could do quite a bit with their bicycles.

Subscribe to our All-Access Digital Edition of the magazine to see the full photo spread that accompanied the piece.

words and photos by Dan Cavallari, D2 Photography, d2photos.net