Cyclists have never had it better in terms of versatile bike options to handle most types of daily rides and racing. Idaho's Kelson Bikes adds another attractive option for cyclists looking for a U.S. handmade frame for road, gravel and cyclocross riding. See details on Kelson's new DNA model below via the company's announcement.

Kelson Bikes is a fairly new company that is breaking into the cyclocross market with a carbon model called the DNA. Located in Rexburg, Idaho, Kelson specializes in custom, handmade carbon bikes.

The DNA's design is optimized to allow the rider to swap between road and ’cross wheels with geometry that strikes a solid balance to give great handling no matter which manner of riding you do. The Kelson DNA is currently available in a semi-custom build with a two-week turnaround time.

Kelson Bikes is based out of Rexburg, Idaho and the company specializes in custom, handmade carbon, steel and titanium bikes.

Each carbon fiber bicycle tube is layed up in-house at the Kelson Workshop. No pre-made tubes, Kelson builds each one from scratch. Each carbon piece is placed by hand and the entire process is carefully monitored. The frame never leaves the workshop at any point. Since Kelson controls the layup schedule of the carbon, they can control the characteristics of each bike and the overall build quality.

The man behind Kelson Bikes is Brian Williams, the frame builder and designer. Williams is a born tinkerer with a meticulous attention to detail. He builds all Kelson frames from start to finish including designing, manufacturing, engineering, and even paint. Every bike that he builds is unique to its individual owner. Williams says, "You can hang your new bike on the wall like a work of art, or you can ride the hell out of it."

Brian Williams is the frame builder and designer. Brian builds Kelson Bikes from start to finish including designing, manufacturing, engineering, and even paint.

Besides carbon, Kelson also produces custom steel and titanium frames but the DNA is their first step into producing a semi-custom production model. Kelson had a lot of input from the riders and racers from DNA Cycling based out of Utah. The goal was to produce a performance-oriented bike that could handle asphalt or dirt equally well. With the adoption of disc brakes for road and cyclocross, as well as the popularity of wide (40mm) tires, the new bike addresses these trends and is built to be able to handle road fondos, gravel grinders, endurance events and singletrack maybe with a splash of bike-packing for good measure.

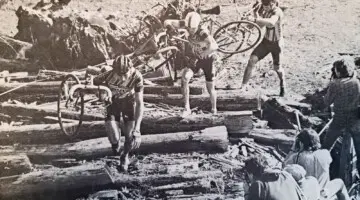

Burke Swindlehurst likes to go where no man has gone before- and with his very own Quiver Killer- here you see him riding the Wasatch Crest Trail in Utah.

Kelson aimed to balance the needs of road, cyclocross and gravel, and believes a good road bike is stable at high speeds and can carve through the apex of a corner quickly. Typically, those attributes are a result of a good combination of head tube angle, fork rake, shorter chainstays and wheelbase, plus bottom bracket heights that lower the center of gravity.

Seth Bradley of DNA crushing dirt and asphalt in Italy on his Quiver Killer.

Cyclocross bikes, on the other hand, typically have longer chainstays for tire clearance and frame clearance. The European style of ’cross bike typically had a higher bottom bracket. But U.S.-based builders have been trending towards a lower than traditional BB height due to faster, less technical American courses, taller cyclocross tires and pedals with improved clearance. European brands have followed this trend lately.

Gearing has also allowed the bikes to broaden their usage and abilities. Events like the Crusher in the Tushar with over 10,000 feet of climbing in just 70 miles require riders to use road racing like tactics and strategy with mountain bike handling and endurance. But events can very drastically and course conditions can change day to day.

Keeping road racing, cyclocross and mountain bike racing and riding in mind, Kelson built a checklist of key features sought for the DNA.

1 - Responsive quick turning- shorter chainstay length (412-415mm)

2 - Stability at high speeds- trail measurements from 58-61mm

3 - Bottom bracket drop of 65-75mm

4 - Connected climbing, shorter chainstays and improved weight distribution

5 - Clearance for at least a 40mm tire

6 - Broad range of gearing options either 1X or compact 2X

7 - Lightweight frame weight (900-1050 grams)

8 - Torsionally stiff with some vertical compliance

9 - Interchangeable drop out inserts for different axle standards

After a summer of careful CAD designing and CNC machining molds in house (not to mention a lot of restless nights and long hours), the DNA geometry (also called internally our "Quiver Killer") was born. Our goal was to build a bike that has the capability to perform well on the road and cyclocross course plus, adapt to crush it at any gravel race.

Of course each frame is custom, meaning top tube, seat tube, and head tube lengths vary for each individual rider. Kelson also lays up and builds all the tubing in house using hand selected materials. Even details such as fiber orientation and number of carbon plies are all taken into consideration according to rider height and weight and riding style. Carbon fiber and the ability to manufacture tooling in house has allowed Kelson Bikes to make tubes to fit the desired frame and component clearances while maintaining the geometry they desire (rather than compromising geometry for the sake of a tube to clear a derailleur or fat tires).

Kelson Bikes is proud to have testimonials from some accomplished cyclists:

"Insane, both up and down. 18 miles of pavement, 5 miles of singletrack and nearly 5k feet of climbing. I couldn't be happier with the bike. Plenty stiff in the BB, climbs like a road bike (just like I'd hoped!) and is amazingly compliant vertically - the dampening on rough surfaces is above and beyond anything I've ridden without some sort of actual suspension" -Burke Swindlehurst (Race Director for Crusher in the Tushar)

The introductory price of $3500 for the carbon DNA includess frame, ENVE fork, and Chris King Headset, more than competitive with other domestic carbon options.

The stock sizes are basically a small (52 cm), medium (55 cm), and large (57 cm). Kelson Bikes' initial run for the DNA will be limited to two frames per size.

More info:

www.kelsonbikes.com

[email protected]

208.317.1327