For today’s Mechanical Monday, we are taking a second look at chain and chain maintenance advice from several experts who know a thing or two about the topic. For another perspective on the topic, we also asked mechanics for their advice on keeping things running smoothly.

For this week’s Mechanical Monday were talking chains and chain maintenance. Most riders have a favorite method for cleaning and lubing chains, along with favorite solvents and lubes. But to make the most of this vital piece of equipment, we’re going to experts Tom Petrie with Connex, Nate Newton with SRAM, Bentley Lee from KMC (who we saw new gear from at the 2016 Sea Otter Classic) and Nick Murdick with Shimano. These industry veterans share their thoughts with us here on some common questions regarding chains, how they work, how they wear and how to take care of chains to keep them lasting as long as possible. Hopefully these experts will get your drivetrain running smoothly and lasting well into summer.

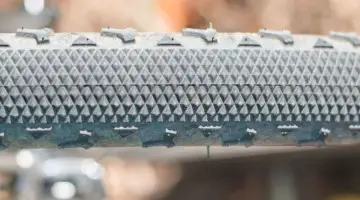

Cyclocross and gravel can wreak havoc on chains. © Cyclocross Magazine

Defining and Measuring Chain Wear

Given our focus on cyclocross racing and, to a slightly lesser extent, gravel rides and races, we often assume that tougher, more adverse conditions wear chains faster than say those found in road riding. But is that really true? And if so, how often should we be replacing our chains?

As Petrie points out, “yes, chains ridden in adverse conditions wear more quickly than otherwise.” But in terms of when to replace, “the metric remains the same–replace them when they’re worn,” he added, a sentiment echoed by Newton. “[SRAM does not] offer a specific mileage recommendation for chain replacement, as conditions and care are such a huge part of chain wear. Simply clean and lube when needed and check chain elongation regularly,” says Newton. Murdick pragmatically added that “I know it’s not what [your readers] want to hear, but … riding conditions make it impossible to predict [chain] service intervals. The best advice is to buy a chain wear indicator and use it from time to time.”

Shimano’s TL-CN42 chain checker. Photo courtesy Shimano.

Newton says that the key is to use “a chain checker that isolates pin wear from roller wear. This provides the most accurate information.“ And KMC’s Lee said that “[e]very 100 miles or so we recommend measuring the chain stretch and doing a visual inspection on the chain to see where the life of your chain is at.”

Of course, our other experts have an opinion on the best chain wear indicator. Petrie suggests the Connex Chain Wear Indicator, a simple “go/no-go” tool that measures wear over 20 links where if the tool lies flat across the chain, it’s time for a new one. KMC’s Lee says ” [t]he best way to measure the chain wear would be to use our Digital Chain Checker to get an exact reading on how much the chain has stretched and to be able to replace the chain at the appropriate time.” And Murdick, with a laugh, says to use “the Shimano TL-CN41 or TL-CN42 of course!”

But how exactly is a chain wearing and what are we checking?

Some readers may already understand, but Murdick explained that “[c]hains are made of a series of outer and inner plates. A pin is pressed into the outer plate but passes through the inner plate and there is a bushing built into that inner plate as well that we rarely see. It holds the two inner plates apart and creates a surface for the roller to ride on. As a chain rolls over the gears on a bike, it wears in a couple of different ways. The inner plate rotates a bit to wrap around the gear, sliding against the chain pin, which remains stationary in relation to the outer plate. The roller rolls on and off the gear but is free to spin all the way around.”

“So,” Murdick continued “[a]s chains wear, the pin gets smaller, the hole in the inner plate gets bigger, the bushing gets thinner in a small section, and the roller gets thinner all the way around. Only the first two are responsible for chain stretch, which is what we care about since that wears down chain rings and cogs.” Petrie emphasized this same point. “The only wear that needs to be considered is the wear between the pin and the interior surface of the inner link collar. As these two surfaces bear on each other, wear occurs [and] the chain gets longer,” he said.

All chains start with a half-inch pitch, the distance from the center of one pin to the next. As chains wear and the pitch grows chains wear cog and ring teeth so the pitch still matches. “Chains are incredibly efficient at wearing down gears to match their pitch,” says Murdick, before warning that “[i]f you put a worn chain on a new drivetrain, the teeth will be worn down to match the chain’s pitch in just a few hours of riding,” a sentiment shared by Petrie. “As the chain gets longer, only the first engaged roller is bearing on the chain ring rather than having all the forces distributed more equally across all the engaged rollers. This wears chain rings and cogs quickly,” confirmed Petrie.

Even 11-speed chains get updates as Connex’s offering did last year. ConneX old (top) vs. then new (bottom) 11-speed chains (a hollow pin version is still available). The chamfered nickel-plated steel plates on the newer chain differentiates the two models. Sea Otter Classic 2015. © Cyclocross Magazine

So how does a chain wear indicator work? Murdick says “[m]ost work by pushing two rollers in opposite directions. But that measures wear on the roller and bushing in addition to the wear we care about between the pin and inner plate. Tool manufacturers can compensate for that since rollers and pins tend to wear at about the same rate. But they can’t account for the size and thickness of things like the pin, bushing, and roller of different chains or the gaps between the roller and bushing. So there’s no way that a tool can work the same on all chains if it pushes two rollers apart.” Shimano’s chain checker “isolates only the elongation of the chain by first pushing two rollers in the same direction, and then measuring the distance between them. It works the same on all chains because it cancels out the roller dimensions,” says Murdick.

Assuming that you’re regularly checking your chain for wear, how much wear are we talking about before a chain will start to damage other drivetrain components like rings and cassettes? Petrie says “1% is the point at which you’re going to see the chain chewing up chain rings and cogs.”

Cleaning Your Chain

If we’re carefully monitoring our chains for signs of wear, there a good chance we’re also cleaning it at that time. But is there such thing as too much cleaning?

Petrie says riders can’t clean their chain too often, but adds that “the chain needs to be cleaned properly. This means a thorough cleaning, not only a cosmetic surface cleaning, and any solvent needs to be removed before the chain is lubricated. Riders can use the Connex Link to make chain maintenance easier because you can take your chain apart by hand, clean it, lube it and reinstall it as often as you like.”

Finish Line offers its No Drip applicator to help apply any brand of lubricant to your chain. © Cyclocross Magazine

And Murdick generally agrees, saying that “[i]f you ride in nasty conditions, dirt is going to get into the lubricant and it will all have to be removed so that you can replace it with fresh, clean chain lube. We recommend keeping [Shimano’s] factory grease around as long as possible but if it gets dirty, it’s going to have to go. The factory grease can last the entire life of the chain in clean conditions, or be useless after a single ride in sloppy, muddy conditions. So there could be such thing as cleaning a chain too often if the bike were ridden in clean conditions but the factory grease is washed away, but that’s not what we’re talking about here.”

SRAM’s Newton concurred. “If the chain is getting cleaned and lube is being washed out of the rollers, but then is not being replaced. As long as the chain is getting re-lubed properly after every cleaning, the chain should be fine,” somewhat echoing Murdick’s hypothetical. But KMC’s Lee suggests keeping it simple. “The degree of how you clean the chain can have a major impact on performance. KMC believes in easy chain maintenance. Powerful degreasers and soaking the chain can actually do more harm than good. A simple brush, spray on light degreaser, and a rag can go a long way,” he noted.

Each of our experts agrees that a chain can’t get too dirty or contaminated to clean. It just takes more work and more thorough cleaning to get the chain back to normal when it’s been used in particularly dirty conditions. “As long as you cleaning your chain after every muddy or sandy condition ride, you should never have a problem with the chain being too contaminated that it is considered to be in not good condition,” said Lee.

Lubricating Your Chain

With all the lubricant variations on the market, is there a best option for a given brand’s chain? To start with, Murdick walked us through the three types of lubricants we typically see, wet and dry lubes and wax.

“Wet lubes come in a variety of different thicknesses, says Murdick. “The thicker and more viscous it is, the longer it will stand up to wet conditions. Manufacturers control the thickness of their products with additives and playing with the mixture of solvent and lubricant. Wet lubes are also tunable in the sense that you can switch from one thickness to another as conditions require. There are a few companies out there that offer multiple different wet lubes that you can bounce back and forth between pretty easily. If you see rain clouds on the horizon, you can simply apply some heavier wet lube on top of what you’ve already got. After the ride, you’ll likely need just a light washing and be able to switch back to a lighter product without having to completely strip the chain of all product,” says Murdick.

Dry lubes are different. “They rely on a solvent to carry their product to the insides of the chain where it’s needed, then the solvent dries and leaves just the solid lubricant behind,” explained Murdick. “That lubricant could be wax, or something like PTFE, molybdenum or ceramics, but since they all need a way to hold those solvents to the chain, most do even if they aren’t specifically a wax lube,” he added.

“There is also sort of a third category,” said Murdick, adding “I’ll just mention it by name since it’s in its own category; Dumonde Tech is a dry lube because there is no oil that stays wet at the end of the application. But instead of using a liquid solvent to deliver a solid to the inside of the chain, the liquid gets to the inside of the chain and then turns to a solid through polymerization when pressure is applied. That means that instead of waiting for the solvent to dry before riding like you would with most dry lubes, you actually want to ride right away and start applying that pressure that starts the polymerization.”

Connex’s Petrie says that “a [c]lean chain with lubricant, any lubricant, is far better than a dirty chain with any lubricant. Depending on the riding conditions, a rider may opt for a wax, or a wet or dry lube. On a test bench some lubes perform incrementally better than others but, at the end of the day, what matters is that the chain be clean and lubricated.” And SRAM’s Newton says that the best bet is to go with a lube that matches your local riding conditions. For Shimano chains, Murdick says that wet lubes are the best bet since those work well with the factory grease that comes in the chains. “[T]he solvent [in wet lubes] also works on our factory grease, allowing it to mix with the lubricant in the wet chain lube,” says Murdick.

Murdick also shared this “pro tip” about wet lubes: “I had heard for years as a shop mechanic that the way to apply wet lube was to put it on sparingly and then wipe away the excess with a rag. The idea is that you only need lube on the inside of the chain so you can wipe off the outside and keep it cleaner. A few years ago, Matt Bracken from Pedro’s suggested to me instead to try wiping the excess lube off right before each ride. I’ve been pretty impressed with how much cleaner the chain stays and how much longer I can go before having to clean and re-apply wet lubes.”

Other Wear Considerations

With the increasing use of 1x drivetrains and wide range cassettes for both cyclocross and gravel events, both of which can be in rather nasty conditions, we had to know if these specialty drivetrains placed any greater wear on our chains.

Wide range cassettes like those seen on this Chris Connor build from NAHBS 2015 shouldn’t appreciably wear chains faster, and may actually increase chain life according to Murdick. © Cyclocross Magazine

Connex and SRAM both say that wide-range cassettes and narrow/wide rings do not appreciably wear chains faster than traditional 2x drivetrains and gear ranges.

In fact, “[w]ide range cassettes by themselves should be good for lessening chain wear,” says Murdick, “because the more teeth on a cog, the less the chain has to articulate to wrap around it.” But, he says that “[s]ingle chain ring drivetrains could be responsible for accelerating wear if the chain ring is small enough that the rider ends up having to use the smaller cogs more frequently. Extreme chain cross over can also accelerate a different kind of wear that we haven’t talked about yet, the lateral flexibility of a chain has an effect on both shift quality and chain retention,” Murdick added.

Petrie and Newton both say that 9, 10 and 11-speed chains show the same wear in the same conditions. “Only 8-speed chains will wear a little longer because there is increased pin surface and inner collar surface areas,” says Petrie from Connex. As for 11-speed chain wear, Murdick says that “[m]anufacturing techniques have come a long way over the years so the narrower outer width is deceiving. It seems like they should wear faster because you’ve got the same wear over a smaller surface area. However, there is actually more surface area contact between the inner plate and the chain pin on 11-speed chains. If you take a chain apart to get to the inner link plate, you can see how the bushing part is formed, and how that’s changed from through the generations,” he said regarding Shimano’s 11-speed chain offerings.

And for KMC, Lee agrees, saying that “new wide range cassettes they do put a lot more stress on the chain given the angles the chain has to accommodate. [But] having a narrow/wide chain ring, we have found that it does not have any additional impact on chain wear over a non-narrow/wide. With all of the testing we have done on our 11-speed chains we have not found that our 11-speed chain wears any faster than 10, 9, or 8-speed chains.”

If chains are going to wear out as it is, can riders opt to run less expensive chains and replace as needed? SRAM’s Newton says that his company’s higher-end offerings have added durability, so it may not be beneficial to try to run less expensive chains more often. “The nickel treatment on our top end chains certainly adds durability, and the hollow pins used on our Red 22 and 1170 chains offer our strongest interface between outer plate and pin. All of our chains can handle the rigors of CX and gravel, though,” said Newton. And the same goes for KMC’s offerings too. “[KMC] always recommend[s] our higher-end chains. There is a lot of designing, coatings, and treatments that go into our higher end chains that not only make them last quite a bit longer over our standard chains but also make them perform much better,” says Lee.

KMC $140 DLC 11 (Diamond-Like Coating) is KMC’s top-of-the-line chain, and comes in a new black and orange color scheme that matches CXM’s logo. Regardless of colors, the chain is said to offer 5,000 miles, compared to 3,000 miles for a standard chain (road conditions). Sea Otter Classic 2016. © Cyclocross Magazine

And the same goes for Shimano’s newer 11-speed chains. “That’s something that’s changed in recent years because of [Shimano’s] new SIL-TEC surface treatment,” said Murdick. “In the past, the difference between [Shimano] chains was mainly which plates got a Zinc-Alloy treatment that made the plates a little tougher and resistant to corrosion. Additionally, top-of-the-line chains also got hollow pins. There wasn’t a durability difference between different levels though, so the idea of using cheaper chains and replacing them more often was at least feasible,” he said.

“The new SIL-TEC surface treatment is a friction reduction treatment though and it increases wear resistance by up to 20%. So while the difference between our 11-speed HG600, HG700, and HG900 chains is still that more parts get the surface treatment as you go up the line, now that does equate to a longer service life. The HG600 chain just gets the treatment on the most important inner plate, the one that rotates around the pin. The HG700 gets the surface treatment on inner and outer plates, and the HG900 gets it on the roller as well,” said Murdick.

Finally, we asked our experts about the cut-outs in side plates and hollow pins and whether those design features were a detriment in muddy or sandy cyclocross racing? “[A]ctually the exact opposite, said KMC’s Lee. “They are an advantage in muddy or sandy racing. The cut-out side plates are actually our ‘mud-shedding’ design, allowing mud to be pushed out the sides of the chain when it passes through the chain ring or cassette instead of getting lodged in between,” he noted.

Thank you to our experts for their insight and tips.

Hopefully, this chain primer, as well as the care details shared here, will help you make the most of your chain.

For more on bike maintenance, see our Mechanical Monday archives.